What is industrial Filtering and why is it important in Manufacturing.

This Article will Explain the reasons why industrial Filtration is important for manufacturing Processes. In most manufacturing Processes it is important to have a Filtration System. all industries, From Food Processing to Pharmaceutical, power Generation, Specific Machinery, Machining.

In this page we will also Explain how we can help you with the Filtration process.

1. Protecting Equipment from Harmful Contaminants

Filtering contaminants during manufacturing is crucial for ensuring product quality, safety, and consistency. Contaminants, such as dust, metal shavings, or chemical residues, can compromise the integrity of the final product, leading to defects, malfunctions, or even health hazards for end-users. By implementing effective filtration systems, manufacturers can prevent these issues, ensuring that their products meet stringent industry standards and customer expectations. Additionally, filtration helps in maintaining the longevity and efficiency of manufacturing equipment by preventing the buildup of harmful particles, reducing maintenance costs and downtime. Ultimately, investing in robust filtration solutions enhances overall operational efficiency and contributes to a cleaner, safer production environment.

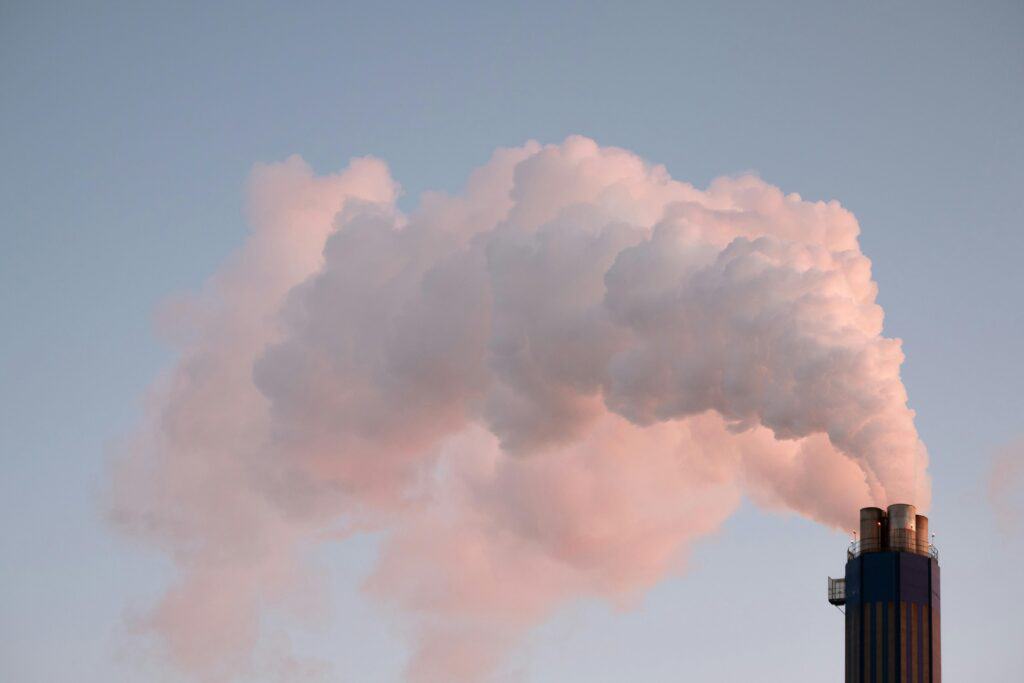

2. Removing Contaminants to Make Clean Streams of Air and Gas

Removing contaminants to make clean streams of air is essential for maintaining a healthy and efficient manufacturing environment. Effective air filtration systems capture dust, pollutants, and other harmful particles, ensuring that the air within the facility is clean and safe for workers. This not only helps in preventing respiratory issues and other health problems but also enhances overall productivity by providing a more comfortable working environment. Clean air streams are also critical in industries where airborne contaminants can compromise product quality, such as electronics or pharmaceuticals. By prioritizing the removal of contaminants, companies can meet regulatory standards, improve employee well-being, and ensure the production of high-quality products. Investing in advanced air filtration technologies is a key step towards achieving these goals and sustaining long-term operational excellence.

3. Protecting Personnel and the Work Environment

1. Health and Safety:

- Ensuring the health and safety of personnel is paramount in any industrial setting. Exposure to harmful contaminants such as dust, fumes, and chemicals can lead to serious health issues, including respiratory problems, skin conditions, and long-term illnesses. By protecting personnel, companies can reduce the risk of workplace injuries and illnesses, leading to a healthier workforce and reducing medical costs and absenteeism.

2. Regulatory Compliance:

- Adhering to local, national, and international regulations regarding air quality and safety standards is crucial. Non-compliance can result in significant fines, legal liabilities, and a damaged reputation. Using effective filtration systems helps companies meet these regulatory requirements and avoid such penalties.

3. Productivity and Efficiency:

- A clean and safe work environment enhances productivity. When personnel feel safe and are healthy, they are more likely to perform their tasks efficiently and effectively. Conversely, a polluted environment can lead to frequent equipment breakdowns and operational disruptions, hampering overall productivity.

4. Environmental Responsibility:

- Protecting the work environment extends beyond the immediate workspace. Effective filtration systems reduce the emission of pollutants into the atmosphere, contributing to environmental conservation efforts. This not only helps in meeting environmental regulations but also aligns with corporate social responsibility initiatives, enhancing the company’s reputation as an environmentally conscious entity.

5. Employee Morale and Retention:

- A commitment to safety and environmental responsibility can boost employee morale. Workers are more likely to stay with a company that prioritizes their well-being and the environment. This can lead to lower turnover rates and a more experienced, dedicated workforce.

How Industrial Filters Help

1. Air Filtration:

- Our industrial filters efficiently remove particulates, dust, and harmful substances from the air, ensuring that the air breathed by personnel is clean and safe. This helps prevent respiratory issues and other health problems caused by poor air quality.

2. Chemical Filtration:

- Specialized filters can remove hazardous chemicals and vapors from the air, protecting workers from exposure to toxic substances. This is particularly important in industries where chemicals are used extensively.

3. Dust Collection:

- Our dust collection systems capture airborne dust and particles generated during manufacturing processes. This not only protects personnel but also maintains equipment efficiency by preventing dust buildup.

4. Environmental Protection:

- By using advanced filtration technology, our filters minimize the release of pollutants into the environment. This helps industries comply with environmental regulations and reduces their carbon footprint.

5. Custom Solutions:

- We provide customized filtration solutions tailored to the specific needs of different industries. Whether it’s for pharmaceutical manufacturing, food processing, or heavy industrial applications, our filters are designed to meet the unique challenges of each environment.

Comments are closed